Statistics and the Bad Reputation

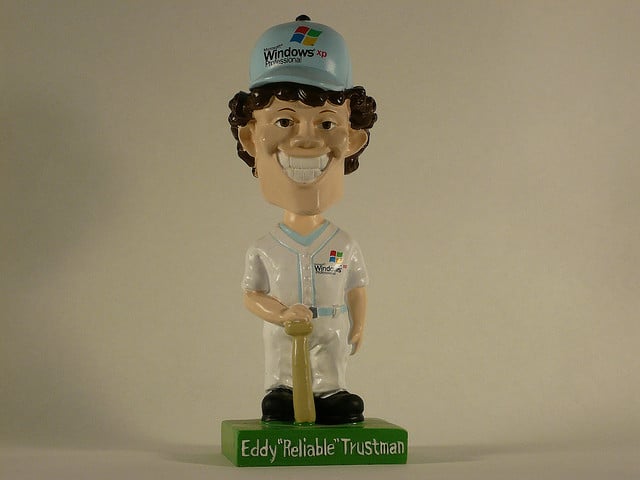

Eddy “Reliable” Trustman (Windows XP Professional)

In a recent reliability seminar I learned that the younger engineers did not have to take a statistics course, nor was it part of other courses, in their undergraduate engineering education. They didn’t dislike their stats class as so many before them have, they just didn’t have the pleasure.

Generally I ask how many ‘enjoyed’ their stats class. That generally gets a chuckle and opens an introduction to the statistics that we need to use for reliability engineering. I’ll have to change my line as more engineers just do not have any background with statistics.

I suspect this is good new for Las Vegas and other gambling based economies.

Statistics are hard

On average there are a few folks that get statistics. No me. There are those that intuitively understand probability and statistics, and demonstrate a mastery of the theory and application. No me.

I like many others that successfully use statistical tools, think carefully, consider the options, check assumptions, recheck the approach, ask for help and still check and recheck the work. Statistics is a tool and allows us to make better decisions. With practice you can get better at selecting the right tool and master the application of a range of tools.

Sure, it’s not easy, yet as many have found, mastering the use of statistics allows they to move forward faster.

Statistics are abused

Politicians, marketers, and others have a message to support and citing an interesting statistic helps. It doesn’t matter that the information is out of context nor clear. When someone claims 89% of those polled like brand x, what does that mean? Did they ask a random sample? Did they stop asking when they got the result they wanted? What was the poll section process and specific questions? What was the context?

The number may have been a simple count of positive responses vs all those questioned. The math results in a statistic, a percentage. It implies the sample represented the entire population. It may or may not, that is not clear.

We hear and read this type of statistic all too often. We discount even the well crafted and supported statistic. We associate distrust with statistics in general given the widespread poor or misleading use.

To me that means, we just need to be sure we are clear, honest and complete with our use of statistics. State the relevant information so others can fully understand. Statistics isn’t just the resulting percentage, it’s the context, too.

Statistics can be wrong

Even working to apply a statistical tool appropriately, there is a finite chance that the laws of random selection will provide a faulty result. If we test 10 items, there is a chance that our conclusion will show a 50% failure rate even though the actually population failure rate is less then 1%. Not likely to happen, yet it could.

We often do not have the luxury of the law of large numbers with our observations.

So, given the reality that we need to make a decision and that using a sample has risk, does that justify not using the sample’s results? No. The alternative of using no data doesn’t seem appealing to me, nor should it to you.

So, what can we do, we:

- Do the best we can with the data we have.

- Do exercise due care to minimize and quantify measurement error.

- Strive to select samples randomly.

- Apply the best analysis available, and,

- Extract as much information from the experiment and analysis as possible.

As with wood working there are many ways to cut a board, with statistics there are many tools. Learn the ones that help you characterize and understand the data you have before you. Master the tools one at a time and use them safely and with confidence.

Fred,

There are a lot of articles in the literature that argue that humans are genetically wired to do probability and statistics wrong, in the brain. I have yet to meet anyone for whom probability and stats was innately understood.

If engineers are no longer getting an introductory course in stats in their undergrad programs, how can they possibly do their jobs in industry? Many of their driving performance requirements are from the engineering specialties.

Sad turn for engineering education.

Mark Powell

And no me too.

Business management was a required undergraduate course, that very few of my classmates attended. I usually used the class to study for “more important things” like differential equations, control systems, assembly language, etc. The business management class covered things like probability distributions, density functions, sampling plans, and other stuff that I figured I’d never use. When I graduated, I took a job as a “Design Assurance” engineer. In that position, I learned about safety, reliability, availability, maintainability, and testability; subjects that were not covered in school. I also learned that I needed to use a lot of statistics, and hardly any differential equations, control theory, or assembly language.

In theory there is no difference between theory and practice; but, in practice, there is.

Sure. A course is statistics is very useful. The same could be said of courses in quality, and even literature, in the engineering curriculum.

The counter question I’d ask is simply: what is the purpose of an undergraduate engineering education. I’d suggest that (1) it gives everyone a set of models that can be used to think about problems facing a business, and (2) it prepares those who want advanced degrees to pursue them.

If you’re required to take a course that someone tells you isn’t important, then I’d suggest that it would be useful to ask who’s giving you that advice and why you should seriously consider it. But the notion that a required course isn’t “important” (in the point above, a business management course that focuses on some basic quality), certainly did not come from the folks who designed the curriculum.

Two other things are true about engineering education: first, as an engineer you won’t use every skill you learned in class on the job and second, you’ll encounter problems that you will have to learn new skills (that is skills you didn’t learn in class) to solve.

I took an introductory statistics course. I loved it: I’d recommend it to others, and, sometimes I even use the tools I learned in it. But what was much more valuable is that I learned a new way of thinking about problems. It is the idea that I have many models (not just statistical ones) that I can use to solve the problems I work that is absolutely essential. In many ways, that’s the point of Fred’s work: if all you have is MTBF, then all you have is one model of reliability engineering, and that can lead to ineffective decision making.

Good discussion all – my only thought is to never stop learning. cheers, Fred

Paul,

I see the purpose of an undergrad engineering education a bit differently.

The customers of an engineering undergrad program are the companies who will be hiring their graduates. Those customers want somebody with the undergrad engineering degree who can get the job done.

Having been involved with corporate advisory boards to engineering departments at a few universities, from both the faculty side and board side, the boards ask the departments to provide the skills they need in industry in the graduates, and the engineering departments usually respond by modifying the degree curricula to meet those needs.

Now, that said, what we may be seeing in fewer engineering graduates having had stats courses may be due to the fact that it is becoming more widely known in industry that the material taught in the old stats 101 courses taken by the folks doing the hiring don’t really work for conducting business very well. Corporate advisory boards may not be pushing for the grads they hire to take the old stats 101 courses so much any more. One can only hope so, and also hope that they will now be asking for stats courses where the grads can actually help them.

Mark Powell