Introduction

When we think of reliability tools, the FMEA often takes the spotlight. But if you’re skipping the P-Diagram, you’re likely missing the very foundation of failure prevention.

In my 15+ years working on field reliability and failure analysis, I’ve come to view the Parameter Diagram (P-Diagram) as the unsung hero of robust design.

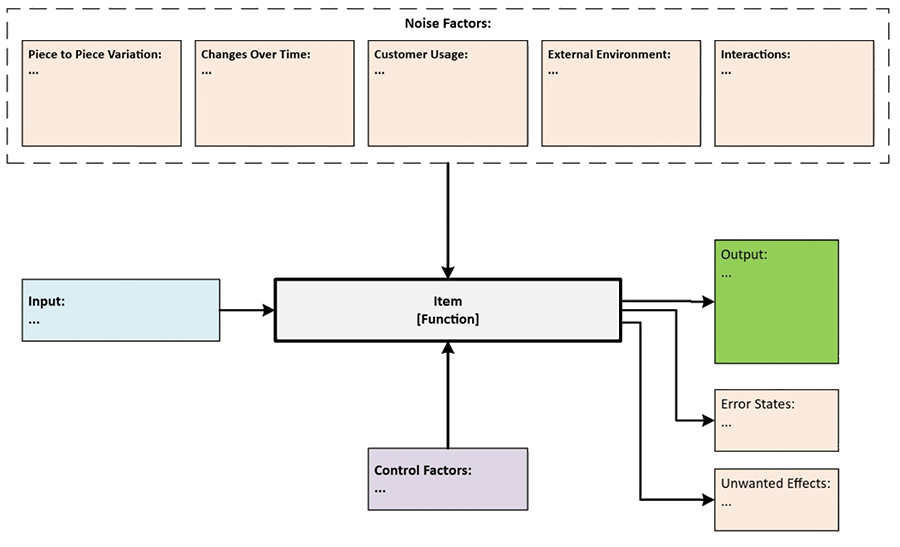

What Is the P-Diagram?

The P-Diagram is a structured framework that:

- Defines the system’s inputs and desired outputs

- Maps out noise factors (external variations that affect performance)

- Highlights control factors, error states, and functional relationships

It’s the first clarity checkpoint — the tool that forces engineers and product teams to fully understand what they are designing, how it operates, and what can go wrong.

Why It’s Underrated (But Crucial)

Most teams jump straight to DFMEA or PFMEA, skipping the groundwork. Here’s what happens when the P-Diagram is ignored:

- Failure modes get missed because the system is not well understood

- Noise factors (like temperature, voltage spikes, or misuse) are assumed instead of analyzed

- FMEAs become checklists, not strategies

A well-structured P-Diagram ensures:

- Failure analysis starts from function, not just components

- You think like the system — from input to error to output

- You capture the voice of real-world variation

The 6 Blocks of a P-Diagram

Here’s what a standard P-Diagram includes:

- Inputs (signals, energy, materials)

- Outputs (intended function, side effects)

- Control Factors (what you design or specify)

- Noise Factors (what you can’t control: environment, wear, user)

- Error States (malfunctions, unintended outputs)

- Functional Description (the core transformation happening in the system)

Real Example: Mobile C-Arm X-ray System

For a mobile C-arm X-ray system, we used a P-Diagram to break down the motor control system—the component responsible for precise movement and positioning of the C-arm around the patient.

| Element | Description |

| Inputs | – User commands (joystick, touchscreen) |

| – Power supply | |

| – Sensor feedback | |

| Control Factors | – Motor type and torque settings |

| – PID control parameters | |

| – Gear ratios | |

| Noise Factors | – Friction variation |

| – Patient table load | |

| – Power fluctuations | |

| – Temperature | |

| Ideal Output | – Smooth, precise, and safe C-arm positioning |

| Error States | – Jerky or delayed motion |

| – Position overshoot | |

| – Incomplete motion path | |

| – Overheating | |

| Mechanism/Function | – Electric motor drive |

| – Feedback control loop | |

| – Mechani |

This structured approach helped us in several ways –

- Clarified Interactions Early On: It forced the team to map the system boundaries—we realized the patient table weight influenced C-arm motion more than we expected.

- Distinguished Controllable vs. Uncontrollable Factors: Separating control factors (e.g., PID parameters) from noise factors (e.g., load variation) helped in tuning motion profiles for better robustness.

- Laid the Foundation for DFMEA: Once we had this breakdown, it was much easier to perform a DFMEA, evaluating risks like positioning failure or motor overcurrent due to specific causes.

- Improved Collaboration Across Teams: The visual clarity of the P-Diagram helped align electrical, mechanical, and software teams—each saw how their domain influenced the output.

Using the P-Diagram for Strategic Reliability

Here’s how I recommend applying it:

- Use it before your FMEA. It feeds the function list and potential failure modes.

- Cross-functional teams only. You need design, systems, test, and field inputs.

- Make it a living doc. Update it as your design evolves.

Conclusion: It’s Not Just a Diagram — It’s a Mindset

If you want to reduce surprises in the field, improve your FMEA quality, and design more robust systems, start with the P-Diagram.

It’s a simple tool — but its power lies in how deeply it forces you to think.

Are you using P-Diagrams in your design reviews? I’d love to hear how you’ve applied it.

Leave a Reply