This article reviews the requirements for building and maintaining vertical, bulk liquid storage tanks. Issues, which affect the care of large storage tanks as well as common problems, are reviewed.

What is a Bulk Liquid Storage Tank?

Bulk liquid tanks can be round, horizontal cylinders, vertical, cylindrical tanks and occasionally spherical vessels. We are concerned here with vertical tanks and vessels whose internal volumes are measured in tens of cubic meters through to hundreds of cubic meters. Examples are oil refinery storage tanks and process chemical storage tanks.

Tank Construction

Storage tanks are made from materials that are chemically compatible with their contents. They are designed to handle the forces resulting from a full tank. Alloy metals, steels, plastics, fibreglass and even woods, as in wine vats, are used. Where it is too costly to make the entire tank from the ideal material, the tank structure is made from less costly materials and the internals are lined with an appropriately compatible surface.

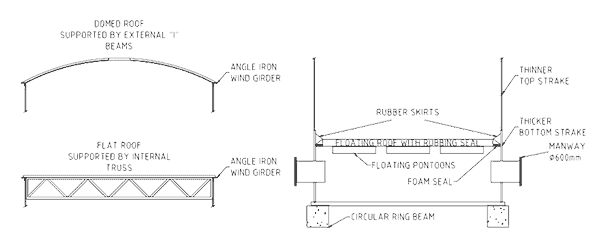

Tank roofs come in several designs. They can be self-supporting cones and domes or supported cones and domes with the structural members either on the inside or outside of the roof. They can be flat top roofs supported by internal structural members or floating roofs that move up or down with the contents and use a seal rubbing against the inside wall to prevent product escape. They can be a combination of floating and covered roofs. Figure 1 shows a vertical, bulk liquid storage tank with a range of roof configurations.

Tanks must be constructed to a recognised engineering standard for the material of construction and the service required of it. A common standard for oil and fuel tanks is American Petroleum Institute (API) 650. The designer calculates wall, roof and floor thickness, weldment sizes and methods, nozzle reinforcements and the need for stiffening and supports to accommodate stresses induced in the tank due to its contents. Allowances are made for specific load conditions such as windage, earthquake, live loads and rain. If the tank contents are liquids with specific gravity less than one (1) the designer builds for the stresses of the water hydrotest.

Tank floors are either sloped towards the wall or sloped to a center sludge sump which is piped away to allow clean out of contaminants. The outside of the floor should have a rain cap right around it to stop rain getting under the floor. If there is a spoon drain around the outside of the tank make sure the height of the spoon drain lip is below the level of the bottom of the tank so no rain water can pool under the floor.

The most stressed part of a vertical tank is at the floor to wall connection. Great effort is taken to minimise residual welding stresses within 300-mm of this weld. For example stress points, like ‘T’ weld joints that form when three plates are butted together, are kept well away from this critical area. Any weld, floor or wall repairs in this area of a tank must comply with recognised tank repair standards such as API 653.

Tank Foundations

A solid, robust foundation is necessary to support a vertical tank. The foundation will take the load of the tank’s self weight and its contents. In particular the foundation must support the localised load of the tank wall. The foundation can be incorporated into the tank plinth for smaller tanks or, as in the case of large vertical tanks, a reinforced, circular concrete ring beam is first constructed for the tank wall. Then the center is in-filled with appropriate clean material and compacted flat for the floor plates to be sat on. Insure in-fill material is chloride free since the presence of chlorides will accelerate the rate of corrosion. Never use beach sand to construct tank bases, as the sea salt will rapidly corrode the metal floor plates.

Some tank settlement will occur over time but the tank foundations and ring beam must not sink too much and must not tilt to far. To insure the long-term stability of the tank it maybe necessary to first conduct tests on the ground for strength and load carrying properties. It is not uncommon to find poor load carrying layers of earth some distance below the surface.

Maintenance Problems

Make the tank foundation and bund of materials compatible with the tank contents. Leaks and spills do occur during operation. If the foundation and bund are corroded they will eventually require substantial repair. If compatible materials are not available then a suitable protective coating should be applied to bund surfaces.

Tank floors sloping to the inside wall mean contaminants and dirt build up against the critical floor to wall joint. If the conditions are right preferential corrosion can occur under the sludge.

For carbon steel tanks the corrosion proofing under the floor is a critical selection. Once the floor goes down it will be inaccessible for the life of the tank. The floor on large tanks is made of plates welded in place while sitting on the base and then the tank wall is built on them. The protective coating on the underside of the floor will be burnt off along the weld line. The coating that remains on the underside of the floor plates is all that will protect them from under-floor corrosion. This coating will need to contain large quantities of inorganic zinc so the zinc will sacrificially corrode over the next 40 – 60 years and protect the steel.

Many forms of corrosion can occur on steel tanks – galvanic, pitting and crevice corrosion is typical. The best long-term protection is to grit blast the steel back to white metal and use an inorganic zinc priming coat at least 75 micron thick. The zinc must be available in a form that will produce a galvanic cell with the steel. On top of the zinc primer the intermediate and top coat are then applied. Always repair damaged paint quickly.

Clean away debris building up against the outside of tank walls or at the crevice between the tank floor and the foundation. The debris causes a differential aeration corrosion cell and any exposed steel under the debris corrodes. Design the base of the tank and the foundation to prevent rainwater running up the crevice between the tank floor and the foundation. The aim is to always have the underside of the floor permanently dry.

Insure the recessed annulus on raised face flanges is painted. If they are not painted they will quickly develop surface rust which will run off with the rain and stain the tank. If this happens on a roof nozzle it and makes an unsightly stain down the tank wall.

Fully weld right around stair treads, handrail stanchions and handrails. Never create a crevice in which rust can develop and produce persistent stains. Leave at least 25-mm clearance between the bottom of kick plates and the top of the tank roof so wind blown debris does not accumulate against the kick plate and cause rusting.

Statutory Inspections

Tanks containing flammables or combustibles require an internal inspection every 10 years. Tanks holding corrosives require an internal inspection every 5 years. These frequencies apply unless it can be proven there will be no leaks from the tanks until at least the next inspection. During these inspections checks are made of the floor to wall welds, floor plate welds, floor plate thickness, wall thickness and wall strake welds. In particular look for worm holing through weld defects or where weld porosity or inclusions have been attacked and penetration into the weld metal has occurred.

Magnetic flux devices are usually used to scan floors. Where there is suspicion of excessive thinning ultrasonic thickness equipment is used to confirm actual floor plate thickness. Walls and roofs are usually spot ultrasonic thickness checked. Sufficient metal thickness must be present for the tank to continue in service. If the floor thickness is below 2.5 mm the floor must be replaced unless an internal lining can be applied which will guarantee the tank’s integrity until at least the next inspection.

The tank internals must be thoroughly cleaned so all surfaces are exposed to a visual inspection. Entry into tanks constitutes a confined space entry and all relevant precautions must be undertaken. The atmosphere inside a tank may be contaminated by the tank’s prior contents, e.g. leaded petrol, and atmospheric testing may be needed to prove the atmosphere is safe to breathe or to confirm breathing apparatus is required.

Internal coatings or linings for corrosion protection must be spark tested to prove continued integrity. Where linings fail integrity testing they must be repaired. Tank outside insulation will need to be removed in enough places to confirm external corrosion is not causing excessive wall thinning.

Ancillary Equipment

During these statutory inspections it is also necessary to test and prove tank valves shut tight and do not leak. Tank level gauges should be inspected and tested for calibration accuracy. Pressure relief and vacuum relief devices must be removed, maintained, tested, recertified and reinstalled. Instrumentation connections like thermowells and pressure transmitter connections need to be inspected for signs of corrosion.

Mike Sondalini – Maintenance Engineer

If you found this interesting, you may like the ebook Process Control Essentials.

I want to make sure that I get the right storage tank. It makes sense that I would want to get one that can hold a lot! I feel like pressurized tanks can hold more, since it condenses the contents.