For the majority of organizations, long-term success is tied directly to the new product development process. Tomorrow’s revenue and growth are tightly bound to how successful you are at launching new products.

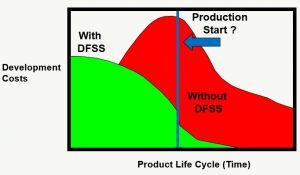

Offering genuinely valuable, high quality products is, more than ever, the best way to capture market share. Also, more investment up-front minimizes overall expense.

…fewer design iterations to achieve the same goals (reduced time to market), more efficient production and delivery processes (reduced operating costs), fewer defects & warranty costs during the entire product life cycle (increased customer satisfaction).

Recall our overarching goal for product development and process improvement: to maximize customer value and minimize cost. Design for Six Sigma can help achieve this goal as follows:

Understand Customer Needs

- Determine customer critical to quality characteristics (CTQ’s) that define product success

- Establish requirements for CTQs (specification limits, mean and variability targets, failure rate and life targets

- Establish part/process sigma goals for the manufacturing/assembly/test process

Define Initial Design Concept

- Formulate design concept and develop models relating key design variables to CTQ’s

- Allocate mean and variability targets and failure rate and life targets to appropriate level

Model Design Performance

- Obtain process capability data or estimates

- Assess nominal design performance and impact of variability

- Calculate probability of satisfying each CTQ

Optimize Design for Value

- Identify any gaps between design and capability

- Define a value function to prioritize CTQs

- Close gaps and maximize value: re-allocate, improve capability, negotiate requirements

Validate Design and Models

- Validate model accuracy for mean and variability

- Verify failure rate and reliability targets

- Verify part and process sigma models

- Monitor and control key x’s that influence customer CTQ’s

- Implement statistical process control (SPC) to maintain part/process sigma

- Refine process capability models and database for use in future projects

Leave a Reply