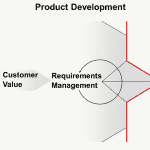

Significant savings in product development costs can be realized with robust validation processes, starting with requirements validation. Validation confirms the product meets customer needs for the products intended use, and answers the question “are we designing the right product?” The “right product” therefore starts with the “right” product requirements. Even a product designed with detailed requirements, but incorrect specification limits, can be considered the “wrong product” (since the product would be rejected by the customer.)

Requirements Validation and Verification

Some basic definitions of requirements and validation are as follows:

Requirement – a requirement is an identifiable element of a function that can be validated, and against which implementation can be verified. A requirement generally defines what capability (functionality) the product shall provide (output) at operating conditions (input). Note that the ouput@input sentence structure lends itself to verification testing where an output can be observed at an input condition.

Validation – validation is a staged process continuing through the development cycle that provides increasing confidence in the correctness and completeness of requirements. Validation answers the question “are we designing the right product?”

Requirements Validation – requirements validation is the process for ensuring that the specified requirements are sufficiently correct, verifiable and complete so that the product meets the needs of customers, users, suppliers, maintainers and regulatory authorities, as well as developers of higher level systems in which the product is used. Ideally, requirements should be validated before design implementation begins. However, in practice the validation of requirements may not be possible until the product is available and can be tested in its operational context.

Verification & Validation Test Procedures – verification answers the question “did we design the product right?” Verification ensures the requirements are met by the product (design verification). Recall that validation ensures the requirements are appropriate to the needs and intended uses of the system; the product may therefore be used to accomplish validation in the customer’s environment, or a validation test. Validation testing may therefore simultaneously serve the purposes of validation as well as verification if tested to ensure valid requirements have been met.

Often, product life cycle processes have a validation phase toward the end of product development. Validation may end with final acceptance of the product by the customer; however, starting validation with voice of the customer and product requirements can save a great deal of time and effort in the product development process.

Leave a Reply